Learn More About Products

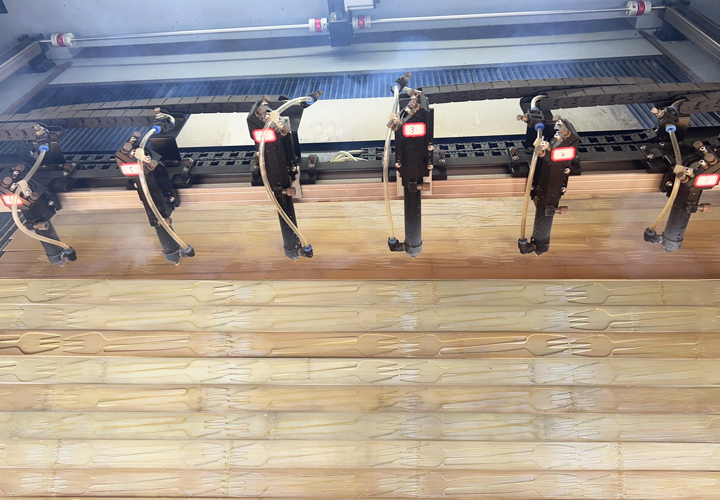

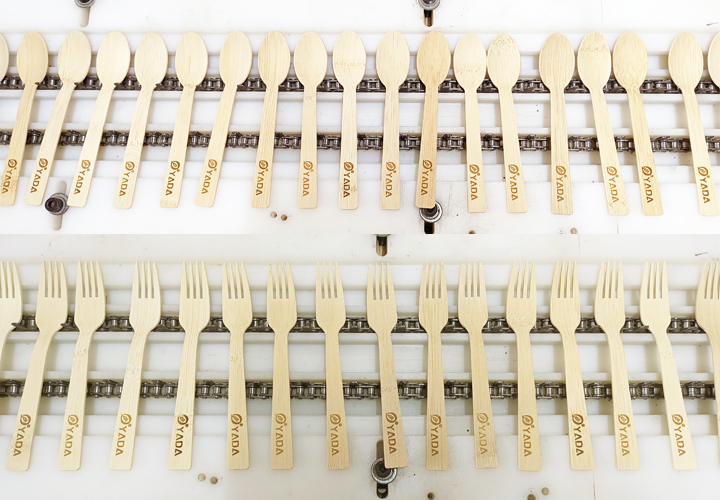

YADA specializes in producing high-quality wooden and bamboo dining cutlery, including knife, fork, spoon, ice cream sticks and spoon, coffee stirrers, skewers, chopsticks, food picks, decorative toothpicks, food container and a new range of household products.