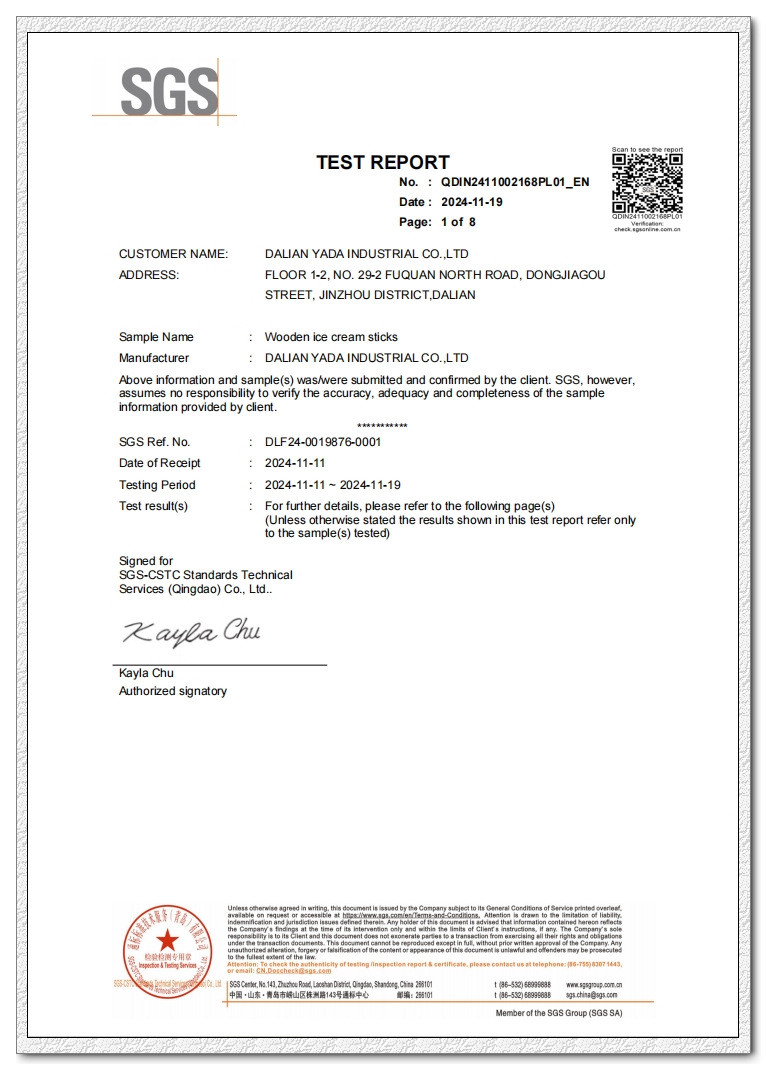

SGS Test Report - Wooden Ice Cream Sticks for Sensory, Defects of Material Quality, Moisture Content, Dimensional tolerance, Defects of Machining

Jan 2,2025

- Period:

- Nov 11,2024 - Nov 11,2025

- Certification bodies:

- SGS-CSTC Standards Technical Services Co., Ltd.

SGS Test Report - Wooden Ice Cream Sticks for Sensory, Defects of Material Quality, Moisture Content, Dimensional tolerance, Defects of Machining

For this year's Ice Cream Stick test report, we have also added index tests for sensory requirements, material defects, water content, dimensional tolerances, processing defects, etc. based on corporate standards. The products are categorized into A, B and C grades according to various aspects such as quality, performance, appearance and price so that consumers can choose the right products according to their needs.

1. Sensory requirements

We have conducted detailed sensory evaluation of each batch of ice cream bars produced, including but not limited to:

Whether the surface is clean and free from pollution;

Whether the texture is smooth;

Whether the odor is inherent to bamboo and wood No peculiar odor;

Whether the package is intact and without damage.

2. Material defects

Material defects are checked according to the original state of bamboo wood, including but not limited to:

Whether the overall color is consistent;

Whether there are insect holes, tree knots and decay;

Whether there are black mineral lines and fluting on the surface;

3. Dimensional specification inspection

In order to ensure that every customer can have a satisfactory experience, all products before leaving the factory must undergo strict dimensional measurements to ensure that the length, width, thickness and other parameters of each ice-cream stick are in line with the design standards.

4. Processing Defect Inspection

The products will be interfered by external substances during the production process, resulting in surface defects. We have refined the types of processing defects, and each batch of products leaving the factory is inspected in accordance with this type of defects, so that customers can better understand the quality and performance of the products.

5. Other important indicators

Moisture content: too high moisture content will lead to deformation, cracking and even rotting of wood, while too low moisture content will increase the hardness of bamboo wood and make it easy to break, so we test the products according to the batch to ensure the performance of the products and the quality of the finished products.

Through this comprehensive and detailed testing process, we hope to provide consumers with safer and more reliable products, and at the same time set a higher quality benchmark for the industry. In the future, we will continue to devote ourselves to technological innovation and service optimization, and strive to meet the growing needs of the market.

If you need to view the original document of our certificate, please contact us to obtain the download permission password.